Products

- We introduce ourselves as one of the leading manufacturer and supplier of water and Waste water equipment’s, established in 2005, having the manufacturing facility of 20,000 Sq. Ft. at M.I.D.C., Butibori, Nagpur.

- At Ganesh Enviro System (P) Ltd., we offer complete solution for any type of waste water. Our design for the Treatment Scheme are the most economical. We manufacture Water Treatment Plant (WTP) Sewage Treatment Plants (STP) and Effluent Treatment Plants (ETP). We manufactured equipment’s like Oil Skimmers, Clarifiers, Aerators, Industrial Agitators, Claritlocculators, HRSCC, Sludge Thickener and Filtration Systems etc.

- Our Equipment’s and treatment systems are approved and appreciated by many user and Consultants on its Quality, Design, Efficiency, Energy Savings and Cost effectiveness.

- We have a galaxy of elite customers in India and Abroad, where over 500 equipment’s & treatment systems are operational.

Clarifiers are generally divided into following categories:

Centrally Driven Clarifier Mechanism:

- Drivers Mounted at center of Bridge

- Rotating Bridge Peripheral Driven

- Clarifier Mechanism

- Centrally Driven Clarifier with Scrum Removal Mechanism

- Lamella / Tube Settlers

CLARIFLOCCULATOR

Clariflocculator Mechanism incorporates two processes i.e. Flocculation and clarification in Single Settling Tank. Clariflocculators are generally of following types.

- Centrally Driven With Independent

- Centrally Driven With Dual Stack Concentric

- Rotating Bridge – Peripheral Drive With 2 / 4 Flocculator Drive. Flocculators.

- Clariflocculator with Prefabricated Flocculator Drive. M.S. Tank (Up to 4 M Dia.)

REACTIVE CLARIFIER: High Rate Solid Contact Clarifier (HRSCC)/ Accelerated Gravity Separator (AGS):

HRSCC constitute Three processes in Single Unit i.e. Mixing, Flocculation and Clarification. The High flow rate and shorter detention result in less foot print area. HRSCC works on principle of solid contact and controlled recirculation to bring previously formed flocs in contact with the raw water.

“HRSCC – Centrally Driven With Dual Stack Concentric Mixer Driver”

SLUDGE THICKNER MECHANISM

Sludge Thickener Mechanism is generally a circular shaped RCC tank with rake and vertical pickets to pump to dewatering equipment or other process as required.GRIT SEPARATOR MECHANISM WITH CLASSIFIER Grit Separator Mechanism consists of i) Grit Removal Scrapper Mechanism ii) Classifier. The settled grit is scrapped by the scrapper mechanism towards the sidewall of the tank. In classifier, reciprocating rake gives the thorough washing for organic liquor.

OIL, GREASE & SCUM REMOVAL MECHANISM

Waste water contains significant amount of Oil, Grease, Fats and Detergents. Oil and Grease has detrimental effect on Biological matter and hence needs to be removed before any treatment. Also waste water from Oil Processing Industries have substantial amount of free oil and the same needs to be removed before biological treatment.

- API Type Oil Skimmer / Trolley Driven Oil Skimmer

- Belt Type Oil Skimmer

- Disc Type Oil Skimmer

AERATION

Aeration is a biological treatment to convert organic matter into Bio Mass and thereby reducing BOD. The Aerators replenish the dissolved oxygen which is consumed by organic matter. Generally Aeration is carried out by using following Aerators.

- Fixed Type Slow Speed Aerators

- Floating Type Slow Speed Aerators

- Floating Type High Speed Aerators

- Retrievable Diffused Aeration System

AGITATORS / MIXERS

The agitation is achieved by generating movement of the liquid phase by means of rotation of impeller of mechanical agitator. The bulk can be composed of different substances and the aim of the operation is to mix it or to improve the efficiency of a reaction by a better contact between reactive products. Also in some cases the bulk is already blended and the aim of agitation is to increase a heat transfer or to maintain particles in suspension to avoid any deposit. The Mechanical agitator consists of a drive device (e.g. Motor, Gear Box), a guiding system of the shaft (Bearings), a shaft and impeller.

- Flash Mixers

- Equalizations Tank Agitator

- Top Entry Agitators for Anaerobic Digester

- Side Entry Agitators for Anaerobic Digester

TREATMENTS

Filtration system is the final treatment stage to furtur improve the quality of treated water before its use. The system is a compact design of rapid sand filtration and actived carbon filtration to polish the water from secondary treatment unit by removing high percentage of filterable BOD/COD and suspended solids.

- Pressure Sand Filters

- Activated Carbon Filters

- Multi Grade Filters

CHEMICAL DOSING SYSTEMS

Water and Waste Water Treatment requires chemicals to be dispensed in small volume within Flocculation, Disinfection, pH correction. Our Chemical Dosing Systems are specifically designed to make dosing technology available with the level of quality dosing required.

PREFABRICATED WATER TREATMENT PLANTS

In prefabricated water treatment plnt, the complete treatment is carried out in prefabricated tanks. The entire unit is mounted on the RCC platform and with minimum piping work and electric cabling, the WTP is put to use.

FILTRATION SYSTEMS

We offer: Supply and Erection of new mechanism for existing RCC Tanks. Revamping of existing mechanism. Up-gradation of existing equipment’s for capacity Enhancement. We have already served sugar Industries, Milk Dairies, Paper Industries, Textiles Industries, Distilleries & breweries, Thermal Power Plants, Cement Industries etc.

STP – Sewage Treatment Plants (Prefabricated Skid/ Mounted / Underground / Above Ground)

With Ganesh Enviro’s engineering expertise, profound design and manufacturing capabilities we deliver the capability to Design, Construct, Install & Commission plants of almost all capacities & technologies. We provides total water & wastewater treatment solutions.

We have already commissioned various sizes of STP at various places like Sports Complexes, Hospitals, Hotels, Colleges, Residential Colonies/cities, and Hostels etc.

River Water / Lake Water / Canal Water / Well Water / Bore Well Water Treatment Plant

Ganesh Enviro’s aim of the treatment processes for raw water are to remove unwanted constituents in the water and to make it safe to drink or fit for a specific purpose in industry or medical applications. Ganesh Enviro uses widely varied techniques to remove contaminants like suspended solids, micro-organism and some dissolved inorganic and organic materials

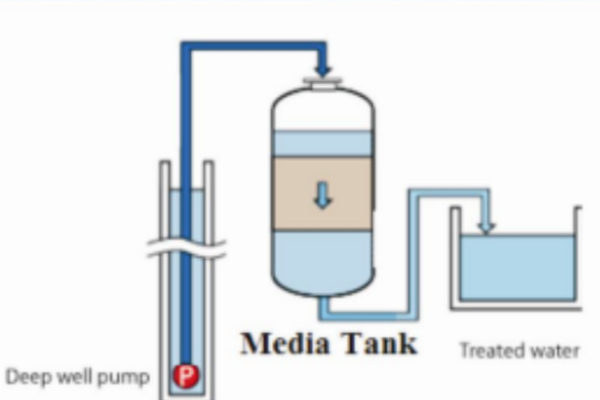

GANESH ENVIRO’s SOLUTION FOR IRON, ARSENIC & MANGANESE REMOVAL

GESPL Engineers developed an innovative system to remove Iron, Manganese and Arsenic present in the water. This standalone system improves the overall water quality. This system is based on the dark brown or blackish media which helps to increase the oxidation processes. At the same time there is no regeneration required as the media remains intact and never gets consumed during the reaction processes. The media used in the processes is black or brown in color and ensures that the proper oxidation happens and at the same time the media should not get consumed.

GESPL’s Electrolysis based DEFLUORIDATION

GESPL has developed the Electrolysis based DE fluoridation technology which comprises a reactor having anode and cathode followed by a sedimentation process chamber where the sludge is collected and spread over a sludge drying bed.

We have already commissioned various sizes of STP at various places like Sports Complexes, Hospitals, Hotels, Colleges, Residential Colonies/cities, and Hostels etc.

GESPL’S Media based DEFLUORIDATION

GESPL has developed a porous natured great adsorbent media which is insoluble in water and can sustain high temperature. This media can remove almost 90% Fluoride.