Processes

GESPL Treatment Process

GESPL’S core competence lies in providing the low-cost and the most effective treatment schemes on the organic strength of waste water. At GESPL, we have implemented various successful Wastewater Treatment scheme by judiciously selecting the Treatment Products.

GESPL Pre-Treatment Process

The purpose of preliminary treatment is to protect the operation of the wastewater treatment plant. This is achieved by removing from wastewater any constituents which can clog or damage pumps, or inference with subsequent treatment processes. The treatment includes:

- Screening (Bar Screen / Racks)

- Oil, Grease and Scrum Removal

- Equalization

- Grit Chambers

- Neutralization

GESPL Physico - Chemical Treatment Process

Physico – chemical treatment of waste water focuses primary on the separation of colloidal particles. This is achieved through the addition of chemicals (called coagulants and flocculants). These change the physical state of the colloids allowing them to remain and indefinitely stable form and therefor form into particles wit flocs settling properties. The treatment includes.

- Regulation coagulation (Rapid Mixing)

- Flocculation (Slow Mixing)

- Sedimentation (Clarification)

GESPL Anaerobic Treatment Process

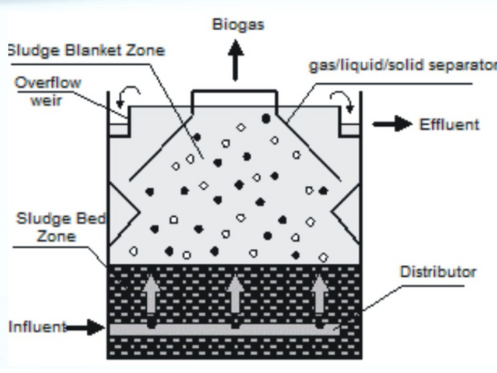

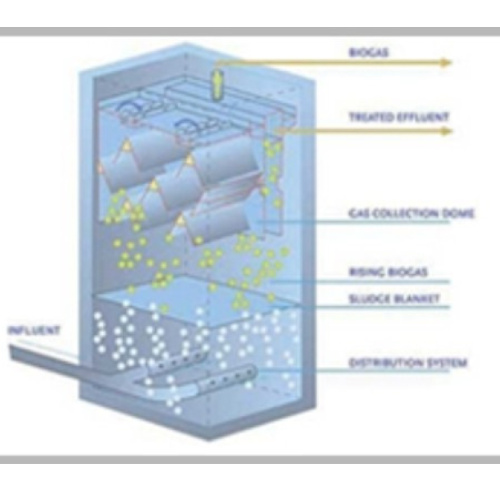

1. GES- UASB REACTOR(GES -UASBR)

Up flow Anaerobic Sludge Blanket Reactor (UASBR) is a single tank process. It offers economical solution to wastewater treatment for various industries like sugar, brewery, dairy, food, confectionary, Pharmaceutical etc. Wastewater enters the reactor from the bottom through feed distribution network and flows upward. The bacteria responsible for digestion process present in Suspended Sludge Blanket treats the waste water which flows through it.

The bacteria present in sludge blanket takes upon microorganisms in wastewater to metabolize it. As a result, it produces biomass and biogas (methane and carbon dioxide). The rising bubble mix the sludge without the assistance of any mechanical device. Our specially designed GLSS [Gas Liquid Solid Separator] work efficiently to keep the granulated sludge inside for the designed load giving Biogas free of any solid entrainment. The clarified effluent is extracted from the top of the tank through network of gutters and launder.

UASB Reactor removes about 70 – 80 % of the COD and BOD load. The biogas that rise to the top can be used as energy (Biogas).or shall be flared off.

2. GES- Continuously Stirred Tank Reactor Digester (GES —CSTR) / Anaerobic Contact Reactor (GES—ACR)

The Continuously Stirred Tank Reactor (GES-CSTR) Digester is a moderate rate, complete mix, anaerobic digestion process. This proven technology maximizes contact between anaerobic biomass and degradable organics, making it a good choice for digesting difficult to treat waste water with high concentration of solids, and fat, oil and grease (FOG). The Primary sludge and waste activated sludge can be digested in GES-CSTR to further increase the biogas production.

Advantages of GES— CSTR Digester:

- Easy Operation.

- Tolerate high concentration of TSS & FOG.

- Operate in completely mixed regime, so no danger of short circuiting.

- S. Tank Digester with Low Foot print area.

- Long HRT to ensure near complete bio-degradation.

GES – Fixed Film Anaerobic Bio Digester (SEG – FFAB Digester)

GES – Fixed Film Anaerobic Bio-Digester is a process in which a fixed matrix (support medium) provides the attachment surface that supports the anaerobic microorganism is the form of Biofilm. Treatment occurs as a waste water flows upwards through this bed and dissolved pollutants are absorbed by biofilm.

Advantages of GES – FFAB Digester

- Less Foot Print Area

- Self-sustaining Bio System, requires no chemicals and moving parts inside digester

- Rugged System with well established know how, Quick Start – up

- Resistance to shock load, so suitable for low and high strength waste water.

- Safety designed economical and inbuilt biogas holder. No separates gas holder is required.

- Existing Tanks can be revamped to GES – FFAB Digester

GESPL Aerobic Treatment Process

1. Moving Bed Biofilm Reactor (GES -MBBR) processes improve | GES-MBBR

Moving Bed Biofilm Reactor (GES-MBBR) processes improve reliability, simply operation, and require less space than traditional wastewater treatment system.

MBBR technology employs thousands of biofilm carriers operating in mixed motion within an aerated wastewater treatment basin. Each individual biocarrier increases productivity through providing protected surface area to support the growth of heterotrophic and autotrophic bacteria within its cells. It is this high-density population of bacteria that achieves high-rate biodegradation within the system, while also offering process reliability and ease of operation.

This technology provides cost-effective treatment with minimal maintenance since MBBR processes self-maintain an optimum level of productive biofilm. Additionally, the biofilm attached to the mobile biocarriers within the system automatically responds to load fluctuations.

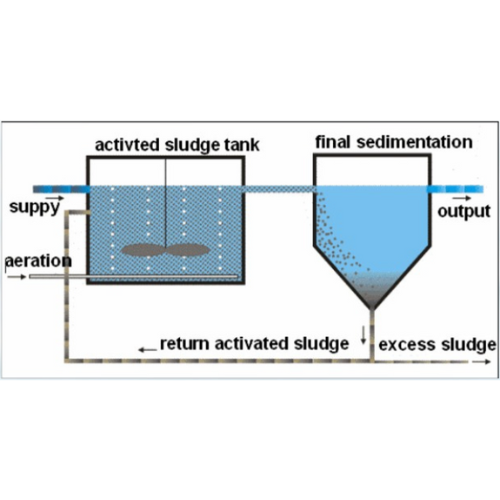

2. GES —- Activated Sludge Process:

GES —- Activated Sludge Process is the conventional and suitable for low and medium strength of wastewater.

GES – ASP also plays an important role in degradation of organic matter escaped from the first stage of Anaerobic Processes. The Aeration is provided either by Fine Bubble Air Diffusers or by Mechanical Aerators.

Mixed liquor from Aeration Tank is taken to Secondary Clarifier for separation of water and Sludge. The Part of Sludge (Active Sludge) is recycled back to Aeration Tank for maintaining the desired MLSS.

3. GES - Submerged Aerobic Fixed Film Reactor (GES- SAFF)

It is based on aerobic attached growth process and used in the secondary treatment of wastewater treatment plant. In this process raw sewage is introduced into the SAFF Reactor where for attached growth process takes place containing contains polymer based bio-media. The aerobic environment in the SAFF is achieved by the use of fine bubble diffused aeration equipment’s, which also serves to maintain the mixed liquor in a completely mixed regime. The mixture of new cells and old cells overflows into a secondary sedimentation tank where the cells are separated from the treated wastewater. A portion of the settled cells is recycled using the horizontal, non-clog, and flooded pumps to maintain the desired concentration of organisms in the SAFF reactor and the remaining portion is wasted to aerobic sludge digester-cum-thickener tank for further sludge treatment.

4. GES — Membrane Bio-Reactor(GES – MBR)

GES — Membrane Bio-Reactor is a process selective membrane eg microfiltration or ultrafiltration is integrated with a biological process — a suspended growth bioreactor.

Membrane Bio-Reactor is a version of the conventional Activated Sludge Process (ASP) system. While the ASP uses a secondary clarifier tank for solid/liquid separation, an MBR uses a membrane for this function. This provides a number of advantages relating to process control and product water quality.

Advantages of GES-MBR

- Small Foot Print Area

- Better Bio-treatment

- High-Quality Effluent

5. GESPL Tertiary Treatment Products

The purpose of tertiary treatment is to provide a final treatment stage to raise the treated water quality to such a level to make it suitable for intended reuse. This step removes different types of pollutants such as organic matter, SS, nutrients, pathogens, and heavy metals that secondary treatment is not able to remove. It includes sedimentation, coagulations, membrane processes, filtration, ion exchange, activated carbon adsorption, electrodialysis, nitrification and denitrification, etc. Prominent are

1) Dis-infection

2) GES- Pressure Sand Filter (GES —PSF )

3) GES~—Activated Carbon Filter (GES —ACF )

4) GES-— Ultra Filtration System (GES -—UF )

5) GES- Reverse Osmosis System (GES—RO) 6) GES- Water Softner (GES—WS)

7) GES-Demineralization Water Treatment Plant (GES—DM)

6. GESPL Sludge Handling System

- Decanter

- Filter Press

- Belt Press

- Centrifuge

7. GESPL: Biogas Flaring Systems

- Biogas Holder

- Flare Stack

- Ignition Systems

- Biogas Generators

- Complete Biogas System